Laboratory Pietra Serena

Stone Cutting, Optimization, and Innovation

Following a path focused on the promotion of Firenzuola’s Pietra Serena and its applications, the company has optimized its internal organization over time, constantly improving its production techniques. Inside the large laboratory, in areas equipped for different types of production, the quarrying of sandstone takes place, including specialized stone cutting processes. The coordinated supply chain makes it possible to obtain a wide range of standardized products, as well as special customizations according to the functional needs of the customer. Processes are carried out by means of modern automatic machinery, which allows for control and regulation of all the working phases, thus optimizing production in full respect of quality.

Pietra Serena is used for the construction of artifacts, the restoration of historical centers, and architectural elements. All this is done in complete synergy with the architects responsible for the works, following a production process that is carried out in accordance with the most modern and efficient conservation techniques.

Stone Cutting and Sandstone Processing

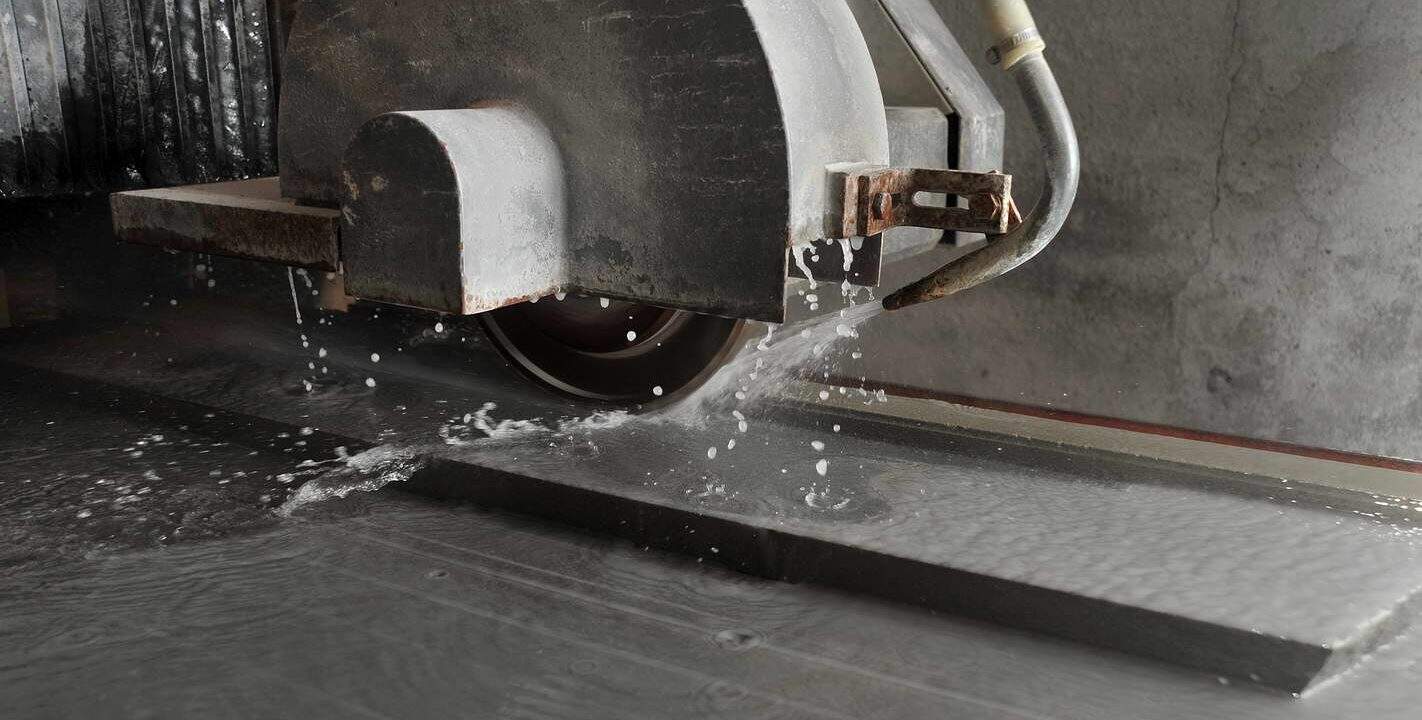

The manufacturing process takes place after the blocks have been transported to the quarry. Sawing is a process that produces slabs of different thicknesses through stone cutting, which is carried out using frames with diamond blades.

Most of the slabs of Pietra Serena di Firenzuola are sold in this form, while the rest are stored, selected, and coded in order to go on to the “finishing” stage, where the slabs are processed according to the customer’s requirements.

Thanks to the experience of its master stonemasons, Calamini is also able to carry out the craftsmanship of great value. The handcrafted artefacts are expertly cared for down to the smallest detail, to satisfy every single customer’s need.

The machinery used, which is essential for a good performance of the processing and finishing activities, include single and multi-blade frame saws and modern automatic machines. Finally, the equipment is completed with tools of the prestigious stonecutter tradition, essential for purely manual processing.